Custom Drilled Wheels have become a cornerstone in the world of car customization, offering an unmatched level of precision and personalization. These wheels are not just about aesthetics; they are about achieving the perfect fitment and performance for your vehicle.

Understanding Custom Drilled Wheels

The Art of Customization in Wheel Design

Customization in the world of wheels is not just about choosing a color or finish. It’s about ensuring that the wheel perfectly fits your vehicle’s specifications. Custom Drilled Wheels are designed to match the exact bolt pattern of your vehicle, ensuring a seamless and safe fit. The process of custom drilling involves precisely machining wheels to match your car’s bolt pattern, ensuring a snug, vibration-free fit.

Pros:

- Tailored fit for your specific vehicle model.

- Enhanced safety and stability on the road.

- Increased variety and choice in wheel designs.

Cons:

- Requires precise measurements and professional installation.

- Can be more costly than standard off-the-shelf wheels.

How Wheels are Custom Drilled: The Process

The process of custom drilling wheels involves several critical steps to ensure precision and accuracy:

Measurement: Accurate Bolt Pattern Assessment

Measurement is the foundation of the custom drilling process. We meticulously measure the bolt pattern, ensuring that the new design aligns perfectly with the vehicle’s specifications.

Design: Crafting the Blueprint

Once the bolt pattern is measured, we design the drilling blueprint. This design considers the size, shape, and placement of the new holes on the wheel. Precision in design is key to the success of the final product.

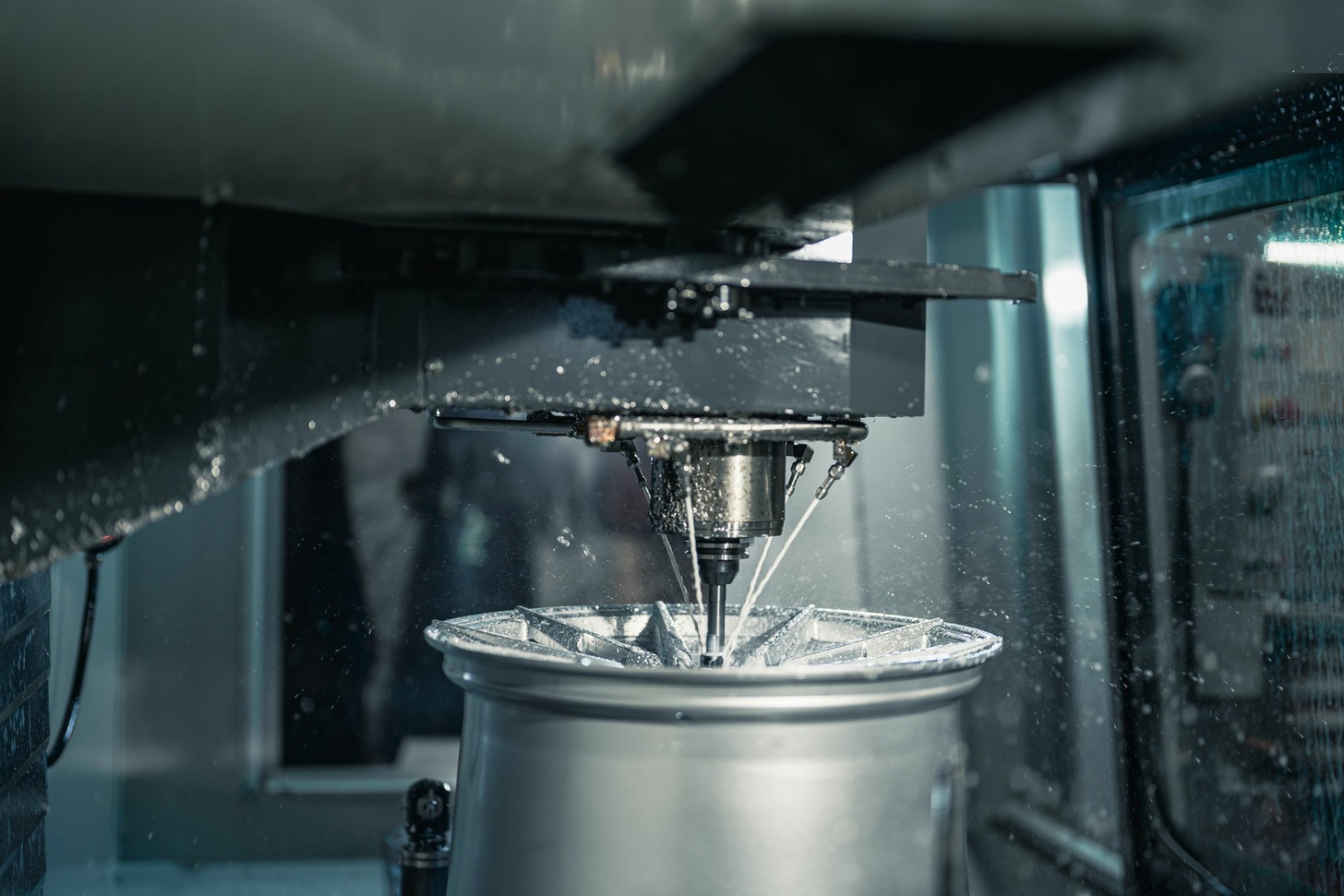

Drilling: Precision in Action

The actual drilling is done using advanced equipment like a drill press or CNC machine for consistent and accurate results. This step is where our expertise and attention to detail come into play, ensuring each hole is perfectly executed.

Finishing: The Final Touches

Post-drilling, the edges of the holes are deburred and smoothed for a proper fit of the lug nuts. The wheel might also undergo refinishing to prevent corrosion and enhance its appearance. The finishing touches are as crucial as the drilling itself, ensuring a flawless end result.

The Role of Bolt Patterns in Custom Drilled Wheels

Ensuring Compatibility and Safety

Understanding bolt patterns is crucial when it comes to Custom Drilled Wheels. The bolt pattern, or bolt circle, is the diameter of an imaginary circle formed by the centers of the wheel lugs. Matching this pattern to your vehicle’s specification is critical for safety and performance. Custom drilling allows for the adjustment of the wheel’s bolt pattern to fit vehicles with different specifications.

Pros:

- Enables the fitting of a broader range of wheel styles to different vehicles.

- Provides a secure, custom fit for enhanced safety and performance.

Cons:

- Requires accurate measurement and understanding of bolt patterns.

- Incompatibility can lead to unsafe driving conditions.

The Benefits of Choosing Custom Drilled Wheels

Elevating Style and Performance

Opting for Custom Drilled Wheels is not just a matter of style; it’s a decision that impacts your vehicle’s performance. These wheels offer a perfect fit, reducing the risk of wheel vibration and ensuring better handling. Moreover, they open up a world of design possibilities, allowing you to choose wheels that truly reflect your style.

Pros:

- Improved handling and ride quality due to the precise fit.

- Access to a wider variety of wheel designs and styles.

Cons:

- Potentially higher costs compared to standard wheels.

- Requires knowledgeable professionals for proper installation.

Custom Drilled Wheels – A Blend of Precision and Style

Custom Drilled Wheels represent the pinnacle of wheel customization, combining precise engineering with aesthetic freedom. They allow car enthusiasts to explore a wider range of wheel options while ensuring a perfect fit and enhanced safety. While the process requires professional expertise and can be costlier, the result is a set of wheels that are uniquely yours in both style and function.

For those passionate about cars and customization, investing in Custom Drilled Wheels is more than just an upgrade; it’s a statement of individuality and a commitment to performance. Contact us today to achieve the perfect fitment for your vehicle!